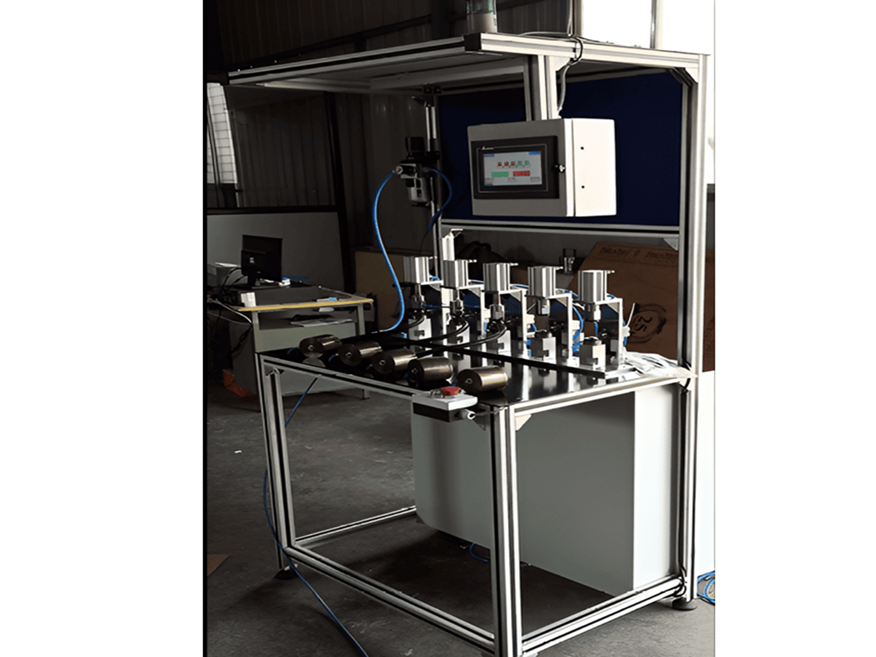

Testing Machine

Testing Machines are precision instruments used to measure the

mechanical properties and performance of materials, components, and

finished products. These machines are critical for quality

assurance, research & development, and compliance testing across

industries such as automotive, construction, electronics, packaging,

and manufacturing. They perform various tests such as tensile

strength, compression, flexural, hardness, and fatigue to ensure

that products meet predefined standards and specifications.

With advanced digital controls, sensors, and data acquisition

systems, modern testing machines offer high accuracy, repeatability,

and detailed analysis. Their user-friendly interface and flexible

test configurations make them suitable for both laboratory and

industrial environments.

Additional Information

- Types of Tests: Tensile, compression, bending,

hardness, fatigue, impact, and peel tests.

- Industries: Automotive, aerospace, plastics,

textiles, construction materials, electronics, and biomedical.

- Automation: Optional integration with PLC,

SCADA, or computer-based data analysis systems.

- Data Output: Provides real-time graphs,

statistical reports, and test certifications.

- Build Quality: Heavy-duty frame with

vibration-free operation for consistent results.

- Compliance: Meets international standards such

as ASTM, ISO, BIS, and DIN.

- Customization: Available in different

capacities, test setups, and software interfaces as per client

requirements.